We regularly receive questions from our customers whether they should choose toggle latch produced from stainless steel or zinc plated steel.

If product price would not be a problem we would suggest to get stainless steel latch. But we all know how important is to be cost effective so here we will explain which material is best suited for your needs.

Stainless steel and Zinc plated steel are two most popular materials used to produce latches and choosing the right one depends on the application and environment where they will be used. Different material determine latch durability, functionality and life span.

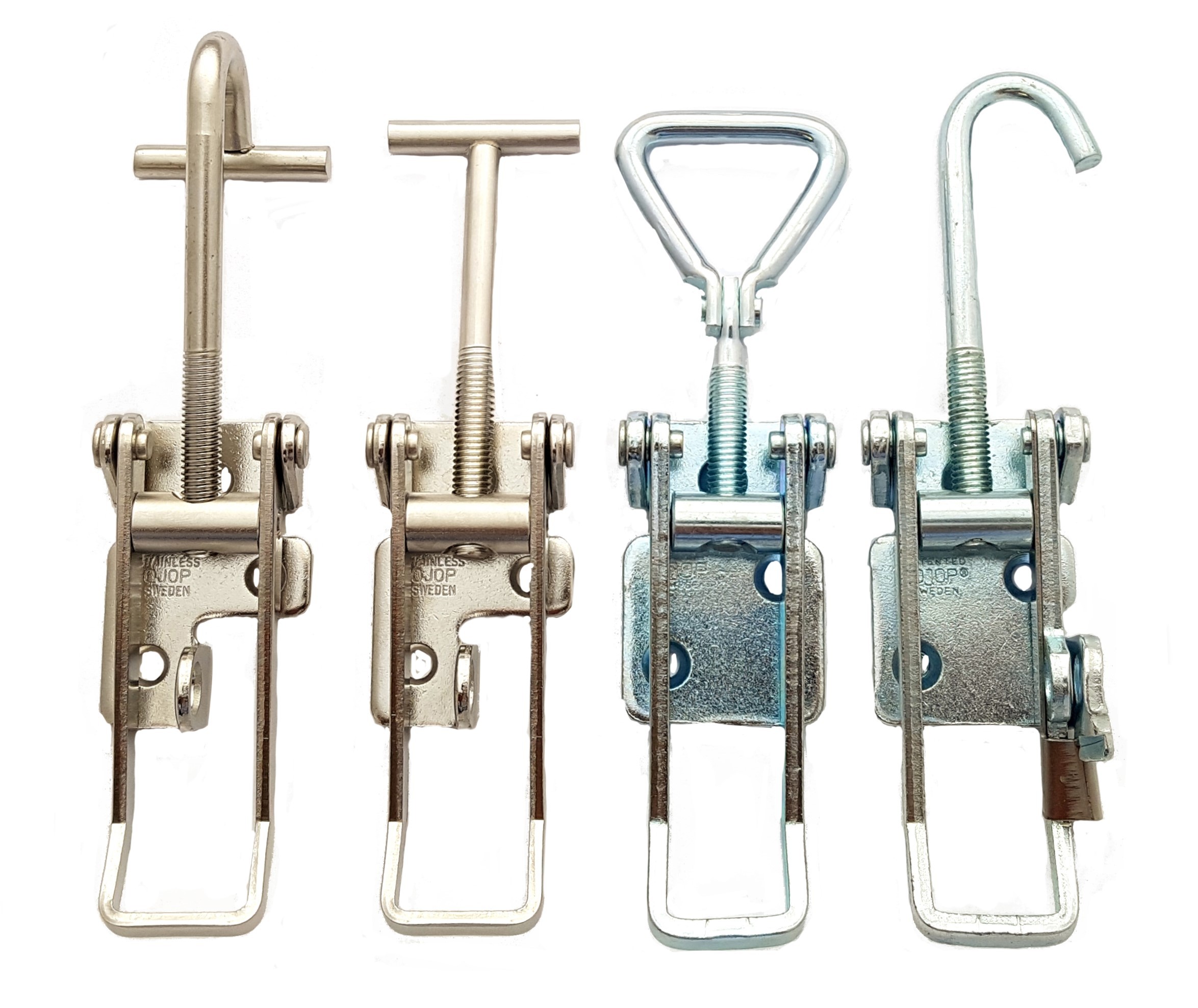

When to choose Stainless steel latches

Stainless steel is usually described as iron based alloy which contains minimum of 10.5% chromium for increased strength and corrosion resistance. There are over 50 stainless steel grades recognized by American Iron and Steel institute (AISI) and we supply latches produced from AISI 304 and AISI 316 Stainless steel.

304 grade stainless steel latches contains 18% chromium and 8% nickel while material used to manufacture 316 stainless steel latches consist of 16% chromium, 11% nickel and added 2.5% molybdenum which helps significantly increase resistance to corrosion. We additionally electropolish 316 stainless steel latches to give that nice smooth and shiny look and further enhance corrosion resistance.

If you need best possible corrosion resistance properties and perfect welding capabilities we would suggest to look for toggle latches produced from 316 stainless steel. These products withstand harsh environmental conditions such as heat, humidity, acid rains, sea salt and exposure to de-icing agents, contacts with chemical elements, such as chlorides, sulfuric acid and bromides. If latches will be used for laboratory equipment, in pharmaceutical and food processing industries we would again offer products from 316 stainless steel as containing molybdenum helps to avoid excessive metallic contamination.

If latches will be used in moderate environmental conditions you could also be looking into 304 grade stainless steel latches. Due high chromium content these latches also have good resistance to corrosion and oxidation. 304 grade stainless steel latches are commonly used in HVAC, automotive, agricultural, construction industries, for industrial equipment and machinery.

When to choose Zinc plated latches

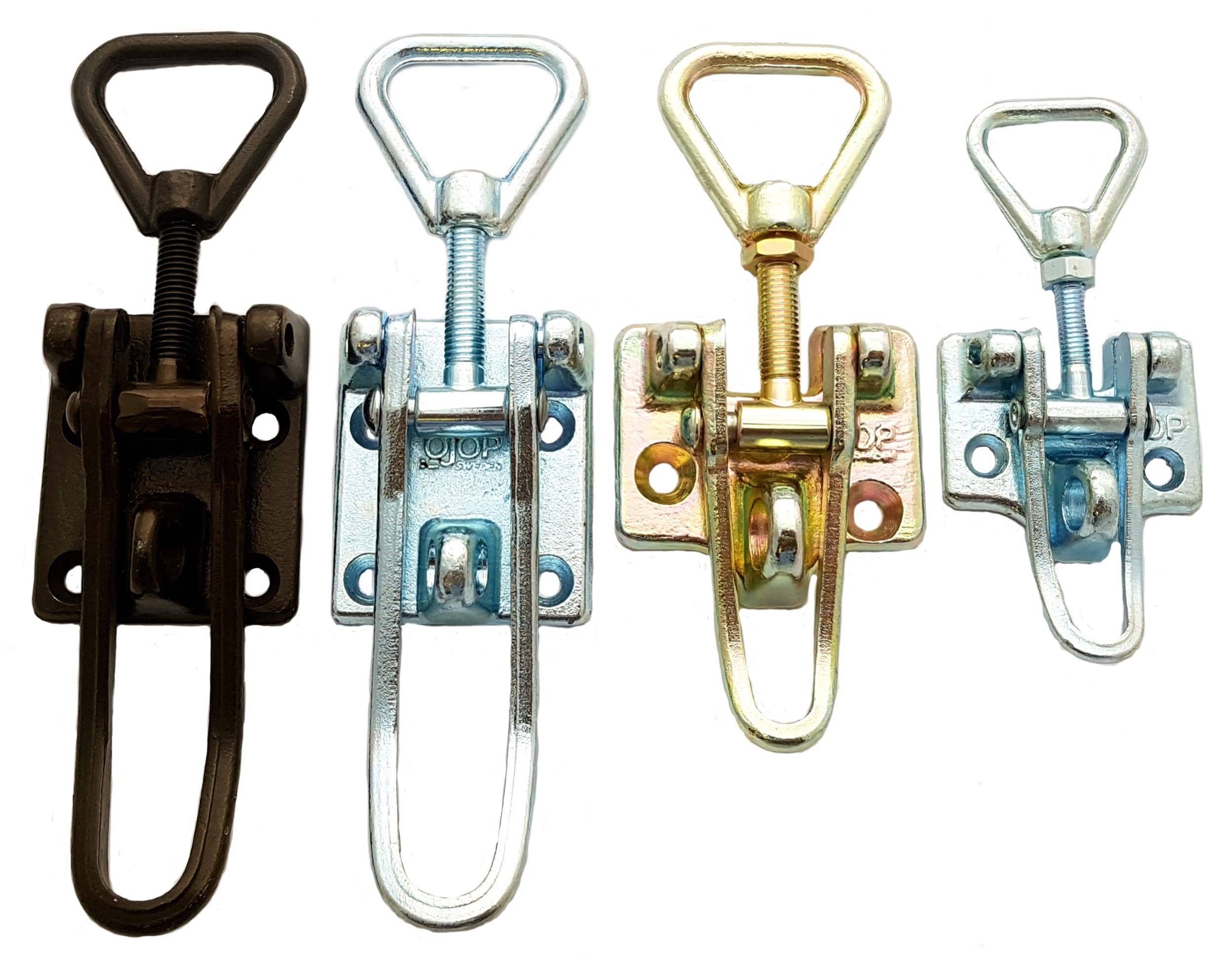

If you are looking of best way for basic steel surface protection against corrosion you will come across zinc. When zinc is electroplated to the surface of iron containing steel, it creates corrosion resistance layer of zinc carbonate which keeps moisture and air from reaching the surface of coated metal and avoid corrosion. Effectiveness of zinc plating combined with relatively low cost has made it a very popular choice through the whole range of industries including latch and fasteners manufacturers.

When comparing zinc plated latches with stainless steel latches cost wise, prices of stainless steel products could be up to 3 times more expensive compared to similar zinc plated latches due to more expensive material and production cost, much shorter die life span. If you are planning to use latches for indoor applications or in light environmental conditions zinc plated products have best price to quality ratio.

These latches have basic corrosion resistance properties, especially if compared with stainless steel, but resistance is still up to 100 times better compared to uncoated steel.

If you are leaning toward zinc plated latches but are not certainly sure that corrosion resistance level will be good enough for your application we suggest a post-plate chromate finish. This is another way to enhance corrosion protection properties of zinc plating. Chromating means immersing zinc plated product into dichromate or chromic acid solution (basically it is a salt which contains chromium and oxygen).

Please contact us if you would like to order this additional surface treatment for your ordered zinc plated steel latches.